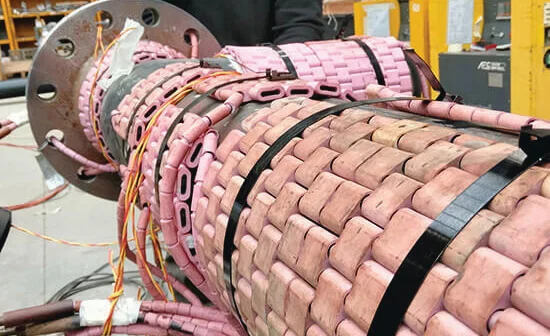

Pre-heating

Heat treatment is a controlled process of heating and cooling metals or alloys to alter their physical and mechanical properties without changing their shape. The primary objectives are to improve material characteristics such as hardness, strength, ductility, toughness, and wear resistance, or to relieve internal stresses developed during manufacturing.

This process involves various methods such as annealing, quenching, tempering, normalizing, and case hardening each tailored to achieve specific material properties.

- Reduces risk of thermal shock and cracking during heat treatment or welding.

- Minimizes internal stresses and distortion in the material.

- Ensures more uniform temperature distribution for consistent results.

- Improves material ductility and workability in subsequent processes.